Pulse Filter Testing

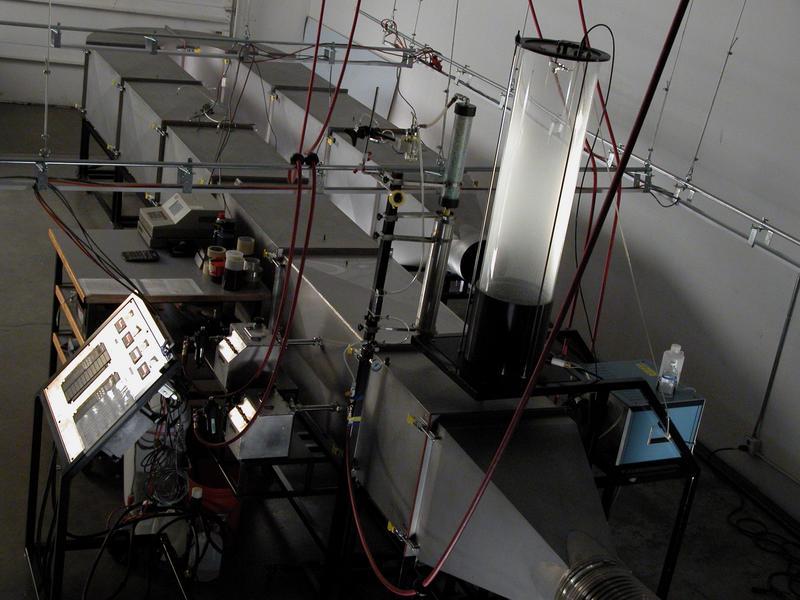

Our new testing duct is capable of controlling and performing tests under specified conditions between:

Pulse Filter Testing

Our new testing duct is capable of controlling and performing tests under specified conditions between:

• 1,000 – 15,000 CFM system airflow

• Greater than 10 inches water gauge (2.5 kPa) restriction

• 0 – 160 PSI (0-1100 kPa) pulse pressures

• 50° to 120° F (10 – 50° C) temperatures (Other temperatures possible)

• 20% – 97+% RH

• 0 – 500 gram per minute dust feed rate

• 20 Kilogram (44 pounds) dust feed capacity

• Uniform mixing of dusts with minimum loss of feed

• Standard or customer specified dusts and aerosols

• Rain or mist simulation

• Full directional water spray (Other fluids may be available)

• 0-120 MPH upstream wind speeds (in addition to system flow)

• Fractional efficiency of test dust and salt at requested intervals

• Water fractional efficiency using proprietary particle counters and methods

• Gravimetric efficiency at requested intervals

• Sampling with 0.45 micrometer membrane filters

• Load up – pulse down sequences

ASHRAE 52.2 / EN 779 / EN 1822

Tests according to ASHRAE 52.2, EN 779, and EN 1822 standards are performed in our U-shaped duct. Our unique particle generation and counting system provides accurate and repeatable test data.

ASHRAE 52.2 / EN 779 / EN 1822

Tests according to ASHRAE 52.2, EN 779, and EN 1822 standards are performed in our U-shaped duct. Our unique particle generation and counting system provides accurate and repeatable test data.

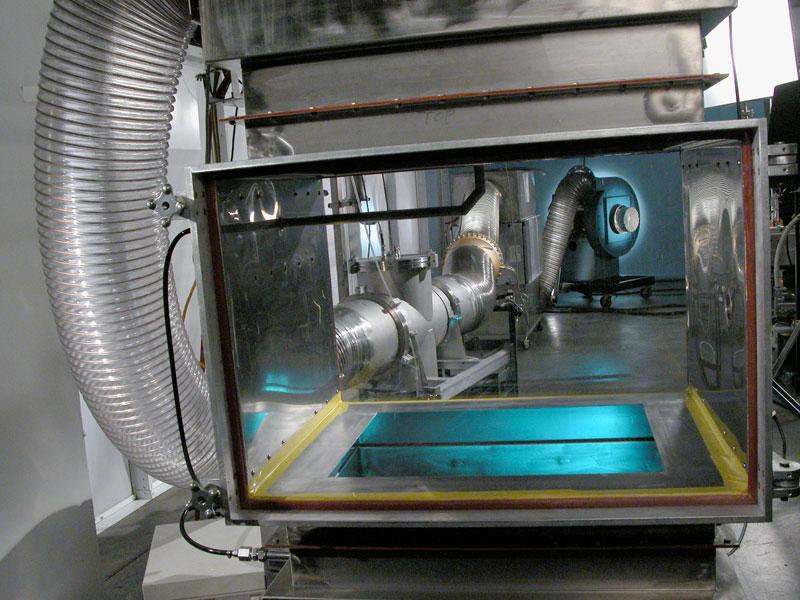

HEPA / ULPA / SAE J1669 / JIS / ASTM / ISO

We can conduct tests for almost all standards in our vertical test system with no particle loss and high accuracy. We are capable of testing filters or flat sheets with efficiencies up to 99.9999%.

HEPA / ULPA / SAE J1669 / JIS / ASTM / ISO

We can conduct tests for almost all standards in our vertical test system with no particle loss and high accuracy. We are capable of testing filters or flat sheets with efficiencies up to 99.9999%.

Dust loading

We perform filtration tests in accordance with ASHRAE 52.1 (dust spot efficiency / arrestance / holding capacity) in our dust loading system.

Dust loading

We perform filtration tests in accordance with ASHRAE 52.1 (dust spot efficiency / arrestance / holding capacity) in our dust loading system.

Scanning Mobility Particle Sizer (SMPS)

We have the capability to measure particle size distributions of nanoparticles ranging from 2.5 to 1000 nanometers. Our SMPS system samples a high resolution of data with accurate and repeatable test results.

Scanning Mobility Particle Sizer (SMPS)

We have the capability to measure particle size distributions of nanoparticles ranging from 2.5 to 1000 nanometers. Our SMPS system samples a high resolution of data with accurate and repeatable test results.