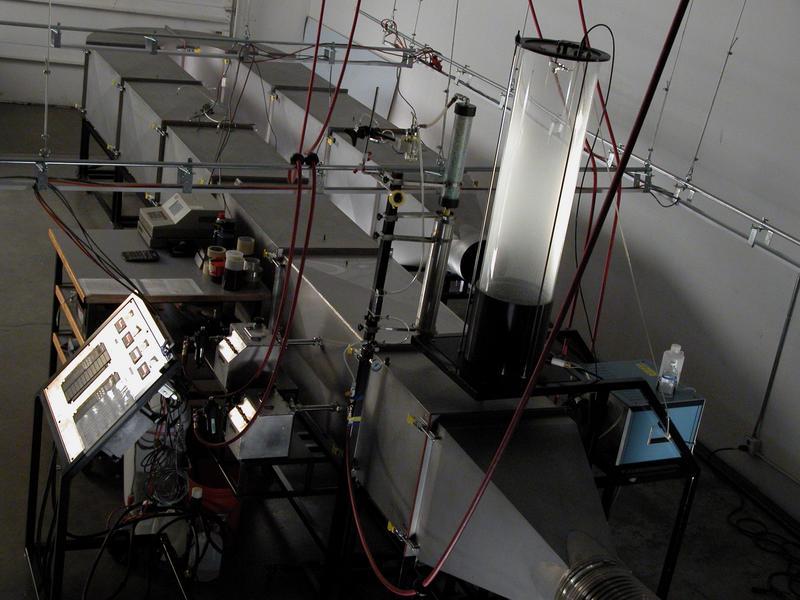

Pulse Filter Testing

Our new testing duct is the perfect tool for in situ simulation of HVAC, heavy automotive, and aerospace environments.

It is capable of controlling and performing tests under specified conditions between:

Pulse Filter Testing

Our new testing duct is the perfect tool for in situ simulation of HVAC, heavy automotive, and aerospace environments.

It is capable of controlling and performing tests under specified conditions between:

• 1,000 – 15,000 CFM system airflow

• Greater than 10 inches water gauge (2.5 kPa) restriction

• 0 – 160 PSI (0-1100 kPa) pulse pressures

• 50° to 120° F (10 – 50° C) temperatures (Other temperatures possible)

• 20% – 97+% RH

• 0 – 500 gram per minute dust feed rate

• 20 Kilogram (44 pounds) dust feed capacity

• Uniform mixing of dusts with minimum loss of feed

• Standard or customer specified dusts and aerosols

• Rain or mist simulation

• Full directional water spray (Other fluids may be available)

• 0-120 MPH upstream wind speeds (in addition to system flow)

• Fractional efficiency of test dust and salt at requested intervals

• Water fractional efficiency using proprietary particle counters and methods

• Gravimetric efficiency at requested intervals

• Sampling with 0.45 micrometer membrane filters

• Load up – pulse down sequences

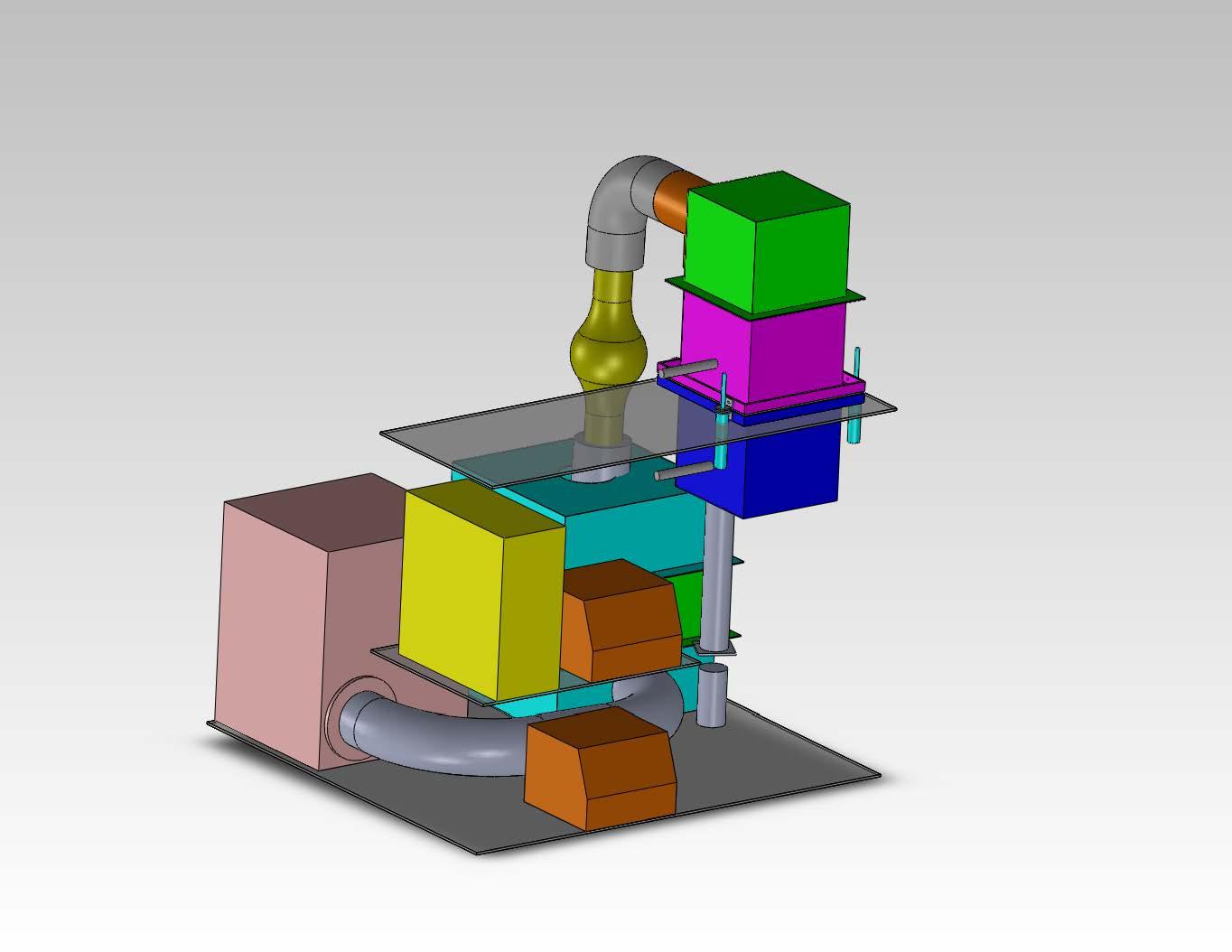

Fully Automated ASHRAE 52.2 Test System

Our ASHRAE 52.2 test system is fully automated for:

Fully Automated ASHRAE 52.2 Test System

Our ASHRAE 52.2 test system is fully automated for:

• Air flow rate settings and adjustments

• Element pressure drop measurements

• Particle generation

• Particle counting

• Efficiency calculations

• MERV classification

• Data storage and processing

Fully Automated Vertical Filter Test System

• Performs fractional efficiency tests up to 99.99999%

Fully Automated Vertical Filter Test System

• Performs fractional efficiency tests up to 99.99999%

• Performs loading and pressure drop measurements

• Used to perform tests based on most standards including HEPA/ULPA, ASHRAE 52.2, EN 779, EN 1822, SAE J1669, JIS, ASTM, and ISO

Our test system is fully automated for:

• Air flow rate settings and adjustments

• Element pressure drop measurements

• Particle counting

• Particle generation

• Efficiency calculations

• Data storage and processing

• Filter scanning

Fully Automated Flat Sheet Test System

Our flat sheet test system is designed for testing of production filter media. It is fully automated to be used by an operator with minimal knowledge of filter testing. The system is designed to provide easy feeding of flat sheets to the test chamber. With the push of a button, efficiency tests will automatically run and data will be processed and stored.

Fully Automated Flat Sheet Test System

Our flat sheet test system is designed for testing of production filter media. It is fully automated to be used by an operator with minimal knowledge of filter testing. The system is designed to provide easy feeding of flat sheets to the test chamber. With the push of a button, efficiency tests will automatically run and data will be processed and stored.

Features:

• Easy flat sheet feeding with a automatic closing of test chamber

• Maximum flat sheet size: 12” x 12”

• Automatic airflow setting

• Automatic pressure drop measurement

• Automatic particle countings

• Data processing for:

- MERV number

- Pass/No Pass

- Initial F classification for EN779

- E, H, U classifications for EN1822